Arch and Cantilever Bridges Explained

Table of Contents

Arch Bridges

The arch form is best suited to deep gorges with steep rocky banks, which furnish efficient natural abutment to receive the heavy thrust exerted by the ribs. In the absence of these natural conditions, the arch usually suffers a disadvantage, because the construction suitable abutment is expensive and time-consuming.

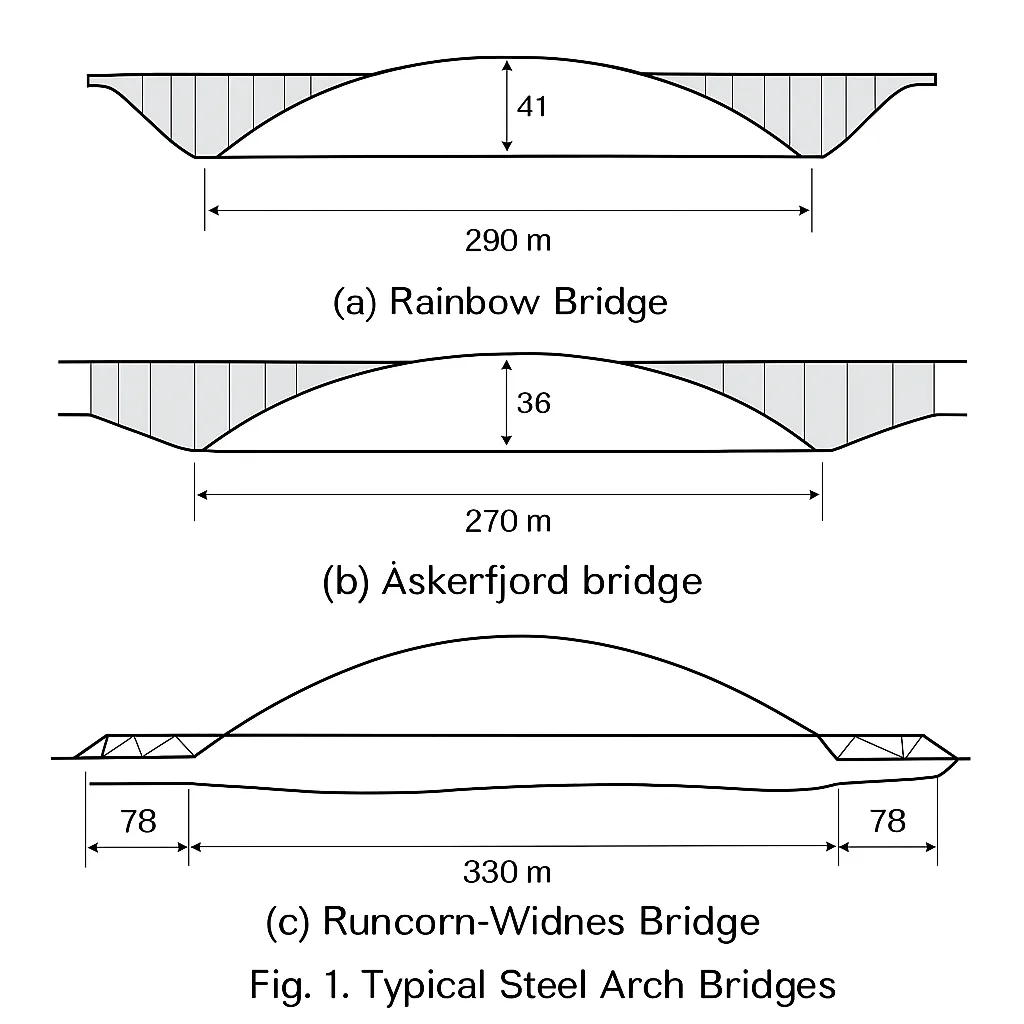

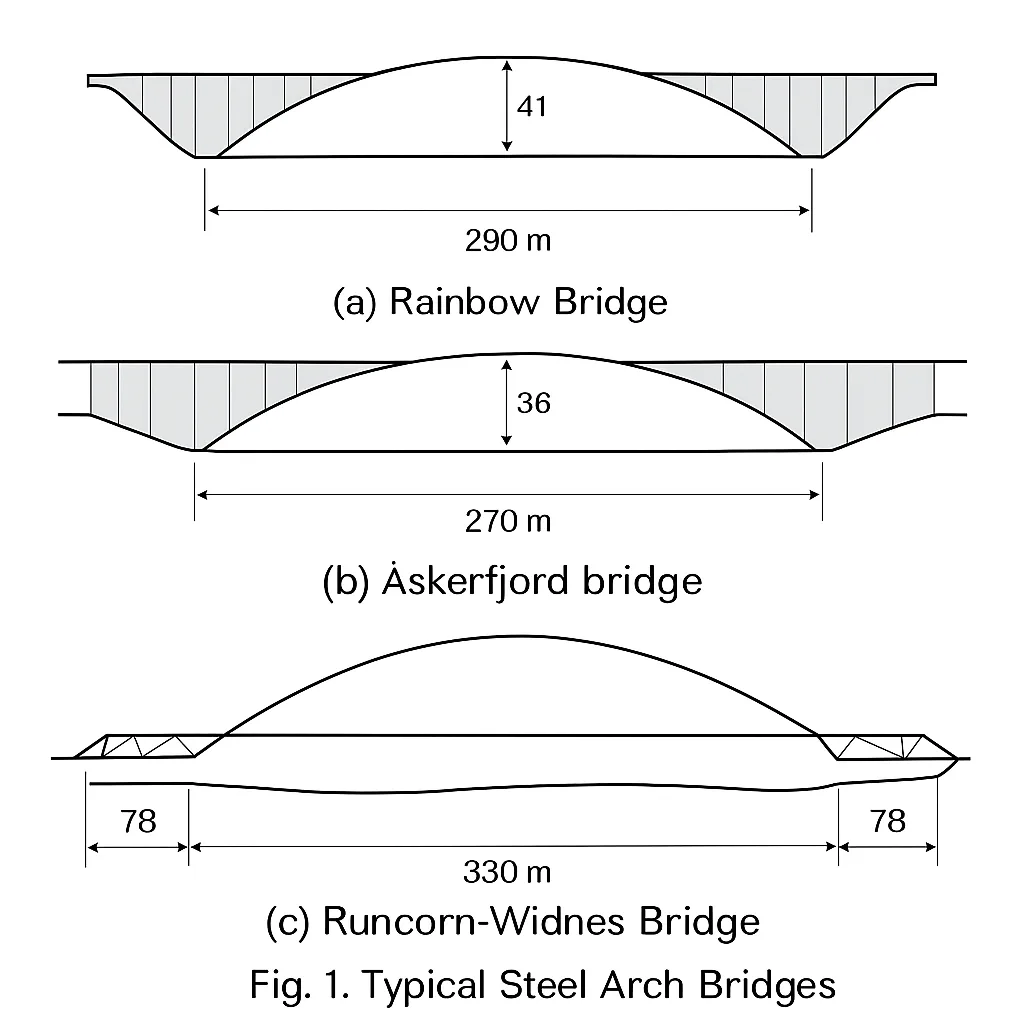

(a) Rainbow Bridge – 230 m

(b) Askersofjord bridge – 270 m

(c) Runcorn-Widnes Bridge – 320 m

The arch form is aesthetically the most pleasing and has been used in steel bridges in an open range of 100 to 250 m. Typical steel arch bridges are shown in Fig. Deck-type spandrel arches can be particularly attractive as in the case of the Rainbow Bridge across the Niagara River at Niagara Falls. The arch profile is intended to reduce bending moments in super superstructure and will be economical in material when compared with an equivalent site simply supported girder or truss. The efficiency is made possible by the horizontal beams provided by the supports, and hence, the site has to be suitable.

The fabrication and erection of an arch bridge would pose more difficult problems than a girder bridge, and should be properly taken into account by the designer. Arch ribs can be hingeless as in the case of the Rainbow Bridge, or may have one, two, or three hinges. The arch rib can consist of a box section as in the Rainbow Bridge, of a tubular section, as in the Askersofjord Bridge in Sweden, or a trussed form as in the Runcorn-Widnes Bridge near Liverpool in England. The rise-span ratio of arches varies widely, but for most arches the value lies in the range of 1 / 4.8 to 1 / 6.

(a) Quebec Railway Bridge – 548 m

(b) Firth of Forth Railway Bridge – 521 m

(c) Howrah Bridge – 457 m

The famous steel arch bridges include:

(i) Eads Bridge in St. Louis, Missouri (1874)

(ii) Garabit Viaduct in France (1884)

(iii) Hell Gate Bridge in New York (1917)

(iv) Bayonne Bridge over Kill Van Kull in New York (1931)

(v) Sydney Harbour Bridge in Sydney, Australia (1932).

Eads Bridge, designed by J.B. Eads, consisted of three spans of 153 m, 168 m, and 153 m. This bridge is also historically important because it was the first bridge in America where:

(a) Steel was used extensively in bridge construction;

(b) The steel material was tested for strong conformity to the specified strength.

(c) pneumatic caissons were used for foundation work; and

(d) The cantilever method of erection was used.

The steel arch bridge designed by Gustave Eiffel is a magnificent two-hinged arch bridge that tapers to the springing, providing an increased lateral stiffness. The Hell Gate Bridge has been considered one of the most beautiful steel bridges in the world. The Hell Gate Bridge, with an overall length between abutments of 512 m is the longest steel bridge in the world.

The famous cantilever bridges include:

(i) Forth Railway Bridge, Scotland (1890) with a two-hinged long span of 521 m;

(ii) Sydney Harbour Bridge with a two-hinged arch span of 503 m, which has been a record bridge till 1977.

The New River Gorge bridge in West Virginia, completed in 1977 with a span of 519 m using weathering steel, has been the world’s largest steel arch bridge till recently. Currently, the title for the world’s longest span arch bridge is held by the Lupu Bridge in Shanghai, China, built in 2004 with a main span of 550 m.

The arch form is likely to go out of adoption for new steel bridges in the near future, in favour of the cable-stayed form of construction, as the latter tends to be more economical and aesthetically pleasing.

Cantilever Bridges

A cantilever bridge with a single main span consists of an anchor arm at either end between the abutment and the pier, a cantilever arm from either pier to the centre of the main span, and a suspended span. Such an arrangement permits a long, clear span for navigation and also facilitates the erection of steel work without the need for supporting falsework.

Steel cantilever bridges came into general use for long-span railway bridges because of the difficulties encountered with suspension bridges. Three well-known examples are shown in Fig. 2. The Firth of Forth Bridge with two main spans of 521 m each, became a milestone in bridge construction on completion in 1890. The designers, John Fowler and Benjamin Baker, used tubular members of fairly large size with riveted construction for the arch ribs to withstand web compressive stresses of 2.68 kN/mm². Though the tubes were large in size, the weight per linear metre of the bridge was still less than that of the Quebec Bridge.

The design of the Quebec bridge was first entrusted to Theodore Cooper, who was then well known for his specifications for railway bridges. The plan envisaged a main span of 549 m with anchor spans of 157 m each, making this bridge the longest span in the world. The first attempt to construct the bridge ended in a complete collapse of the south arm, killing 75 men (1907). The failure was due to the miscalculation of dead load and the wrong design of compression members, which were not noticed in time. The design was revived by H.A. Voutlet, and the structure was reconstructed in 1917 with the same main span.

Howrah Bridge, with a main span of 457m was the third-longest span cantilever bridge in the world at the time of its construction (1943). The bridge was erected by commencing at the two anchor spans and advancing towards the center with the use of crawler cranes moving on the upper chords. The closure at the middle was obtained by means of sixteen hydraulic jacks of 800 t capacity each. The construction was successfully completed with very close precision

Arch and Cantilever Bridges Explained

- What are the Abutments? Know Its Types & Functions with suitable example:- https://engineerlatest.com/what-are-the-abutments-know-its-types-functions-with-suitable-example/

- Characteristic of an ideal site for a Bridge:- https://engineerlatest.com/characteristic-of-an-ideal-site-for-a-bridge/

- The Arch bridges and Cantilever Bridges:- https://engineerlatest.com/the-arch-bridges-and-cantilever-bridges/

- Steel Bridges Types and Benefits:- https://engineerlatest.com/steel-bridges-types-and-benefits/

- Truss Bridges, Types, Design Benefits, and Components Overview:- https://engineerlatest.com/truss-bridges-types-design-benefits-and-components-overview/

- Footings and Foundations Explained: Types, Functions, and IS 456 Guidelines:-

Post Comment