Bitumen Tests Explained: Softening, Ductility & Flash Point

Table of Contents

Bitumen Tests Explained: Softening, Ductility & Flash Point, Bitumen Tests in Highway Engineering: Softening Point, Ductility, Flash & Fire Point Explained

BITUMEN

- obtained by fractional distillation of crude oil.

- soluble in carbon tetra chloride & carbon disulphide.

- less resistance to temp.

- more resistance to weathering.

- less resistance to temp.

- used for damp proof course.

TAR

- obtained by destructive distillation of coal & wood.

- soluble in toluene.

- more resistance to temperature.

- less resistance to weathering.

- more resistance to temp.

- used for coating a wooden frame.

- RT-1 – lowest viscosity → for surface painting

- RT-4 – premix in macadam.

- RT-5 – grouting (highest viscosity)

Form of Bitumen

1) Cutback bitumen

- obtained by reducing the viscosity of bitumen wit/’;h diluents (volatile).

- It is used in colder regions.

- Cutbacks are designated by numerals representing viscous cutback.

e.g. RC-2 is more thick than RC-1 but RC-1, MC-2, SC-2 have same viscosity.

(1) Slow curing cutback (SC)

- obtained by blending with high-boiling-point gas oil. (naphtha or gasoline oil).

(2) Medium curing cutback

- They have good wetting properties.

- Bitumen is flux with kerosene, light diesel oil.

(3) Rapid curing cutback

- They have penetration value of 80 to 120.

- flux with naphtha or gasoline oil.

2) Emulsion bitumen

- It is two-phase system consisting of two immiscible liquids.

- It is used rainy season.

- Emulsion can be used for soil stabilization in desserts.

- Bitumen/tar content in emulsion range for 40% to 60%, and remaining portion is water.

• Emulsion bitumen

- Slow setting bitumen – used for surface dressing work.

- Medium setting bitumen – used for patch up work.

- Rapid setting bitumen –

TEST ON BITUMEN

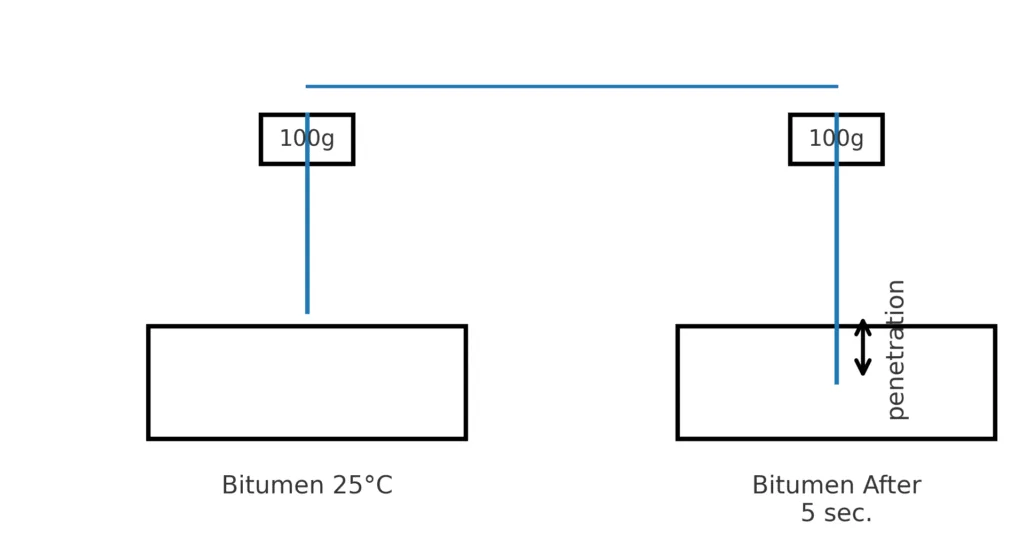

1) Penetration test

- Determines the hardness indirectly.

- Unit of penetration is 1/10 mm

- Load = 100g

- Penetration value ↑ → Hardness ↓

- Example: 80/100 means penetration of 8–10 mm.

- Common grades are 80/40, 60/10 & 80/100.

- Tars are soft, so a penetration test is not used.

2) Solubility

- It is used to measure the quantity of impurity in bitumen with the help of CS₂ and CCl₄.

- Solubility of bitumen in trichloroethylene is a measure of its purity.

- As per IRC, insoluble material should not be greater than 1%.

3) Ductility test

- It is a measure of the elasticity of the material.

- It should be capable of being stretched without breaking.

- Stretching standard briquette having c/s area 1 sq. cm at 27°C at a rate of pull being 5 cm/min → 50 mm/min.

As per ISI, the minimum value of ductility is 75 cm.

4) Spot test

- This test is used to determine overheated or cracked bitumen.

- More sensitivity than the solubility test for the detection of cracking.

- 2 gm of bitumen is mixed with 10 ml of naphthalene, and the solution is prepared & placed in a filter paper.

- Stain spot → uniform colour → uncracked bitumen

- Stain → annular ring thick, brown or black at centre & fair at periphery → overheated or cracked bitumen

5) Viscosity of bitumen (cup viscometer)

- The property of bitumen which resists the flow due to internal friction.

- Viscosity of liquid bitumen measured by efflux viscometer.

- Methods used are STV (Standard Tar Viscometer), Saybolt, Furol, Redwood & Engler.

- Furol viscosity is a standardised test.

- In this test, the time taken is in seconds at the given temperature. 60°C.

- When the time taken is more, the viscosity of bitumen is higher.

- More viscosity → less compaction

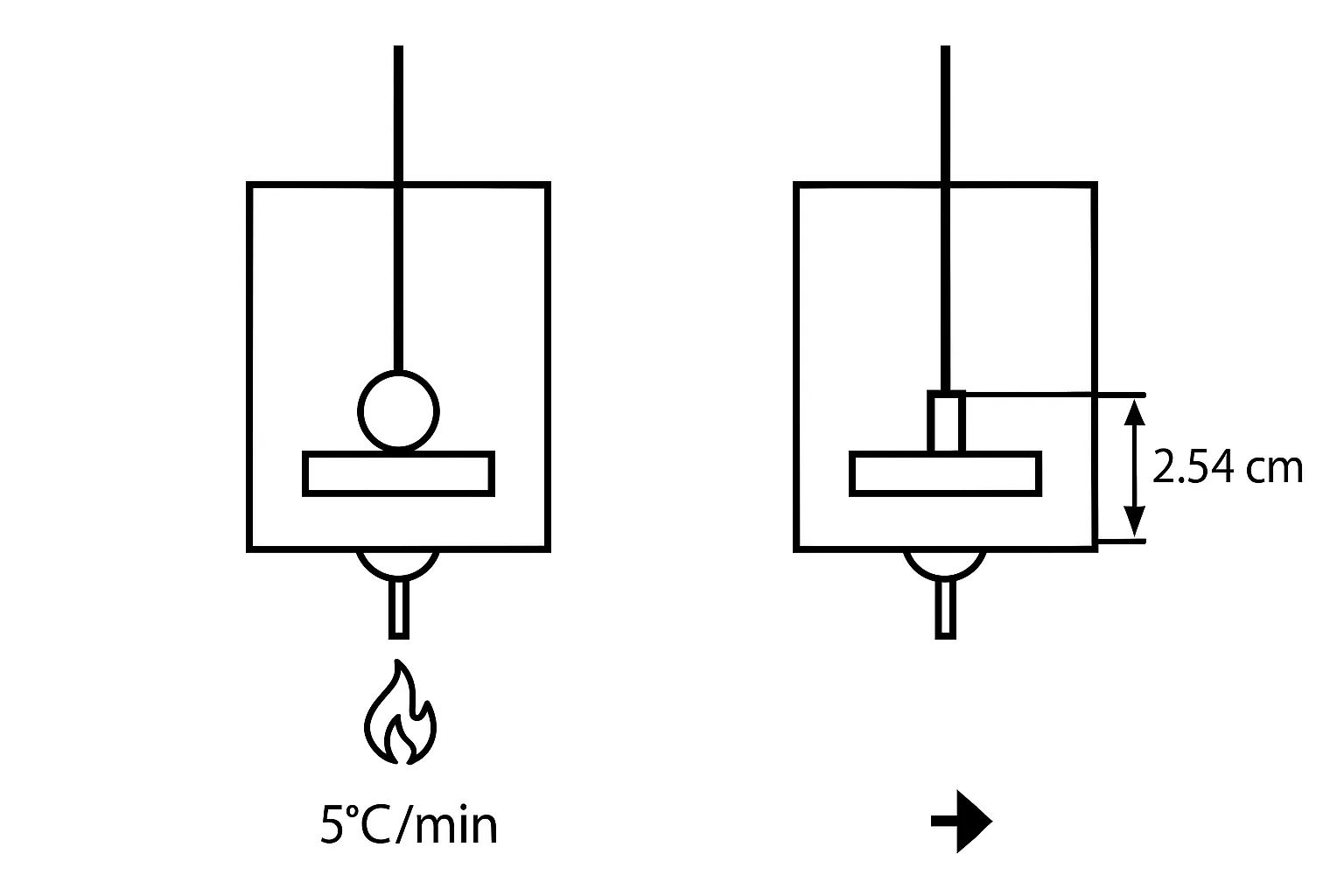

6) Softening point

- Measured by the ring & ball apparatus.

- Softening point is the temperature at which bitumen attains a particular degree of softness.

- More softening point = the material is more harder.

- Softening point ⇒ 35°C to 70°C

7) Flash & Fire point

- Flash point – Flash point of a material is the lowest temperature at which vapours take fire in the form of a flash.

- Fire point – Temperature at which the material gets burnt (burns for 5 sec at least).

- In this test, the apparatus used is Pensky–Marten’s close cup apparatus.

- Flash point ⇒ 175°C (specified by IRC).

- Safe limit for heating bitumen is normally 50°C below the flash point.

8) Specific Gravity

- Determined by the pycnometer method.

- Measurements are taken at 27°C. The specific gravity is generally 1.0.

- Bitumen ⇒ 0.97 – 1.02

- Tar ⇒ 1.10 – 1.25

9) Water Content Method

- Maximum water content in bitumen should not exceed 0.2% by weight.

Bitumen Tests Explained: Softening, Ductility & Flash Point

- History of Road Construction and Highway Planning in India: – https://engineerlatest.com/history-of-road-construction-and-highway-planning-in-india/

- Rail Joints in Railways: Types, Applications, and Importance:- https://engineerlatest.com/rail-joints-in-railways-types-applications-and-importance/

1 comment