Defects in Timber

Table of Contents

Defects in Timber Due to Natural Forces

- Burls:- is a growth on a tree where the grain has become distorted. It usually appears as a spherical outgrowth full of tiny knots on a limb or trunk of a tree. A tree that experiences stress will develop a burl. A virus, fungus, or injury could be the cause.

- Callus:- it indicates soft tissues or skin that cover the wound of trees.

- Chemical stain:- Discolored due to chemical action on trees.

- Coarse grain:- Trees grow rapidly hence, annual rings are widened and hence timber possesses less strength.

- Deadwood:- Timber is obtained from dead-standing trees.

- Druxiness:- White decay spots of fungi.

- Foxiness:- This defect is indicated by a red or yellow tinge in wood or reddish brown stains or spots around the pith of the tree discoloring the timber it is generated by wood or by inadequate ventilation during storage.

- Knots:- These are the bases of branches or limbs that are broken or cut off from the tree. The stem provides nutrition to the section from which the branch is taken for a considerable amount of time. Ultimately, it leads to the creation of knots, which are rigid, black rings. Knots become a source of weakness because they interrupt the continuity of the wood fibers.

CLASSIFICATION OF KNOTS BASED ON SIZES

- PIN KNOT:- diameter upto 6.50mm

- SMALL KNOT:- diameter upto 6.5 and 20mm

- MEDIUM KNOT:- diameter between 20 and 40mm

- LARGE KNOT:- diameter greater than 40mm.

CLASSIFICATION OF KNOTS BASED ON FORM AND QUALITY

- DEAD KNOT:- knot which is separated from the body of wood.it is not safe to use wood with such a knot for engineering purposes.

- DECAYED KNOT:- popularly known as unsound knot and formed by the action of fungi on wood.

- LIVE KNOT:- it is thoroughly fixed in wood and cannot separated from the body of wood.it is free from cracks and decay. Wood containing this knot can be used for engineering purposes.

- LOOSE KNOT:- it is the preliminary stage of the dead knot.

- ROUND KNOT:- the cross-section of this type of knot is either round or oval.

- TIGHT KNOT:- it is the preliminary stage of the live knot. The fibers of the knot are firmly held in surrounding wood.

- Rind Galls ⟹ the rind means bark and gall indicates abnormal growth, hence peculiarly curved swelling found on the body of a tree is known as rind gall. brought on by either wood or inadequate ventilation during storage. and not durable.

- Shakes ⟹ These are cracks which partly or completely separate and are often found in older trees that grow in wet areas. These are either radial or tangential shakes-

- Star shakes: – radial splits in timber originating from bark and narrowing towards pith are known as star shakes. These spilled tend to open more and more as the timber seasoned.

- Heartshakes: – generally occur in over mature trees. More frequent in hardwoods than in conifers. They are due to the shrinkage of the interior part of the tree which is approaching maturity.

- Frost shakes: – begins on the outside where moisture from rain or other means has penetrated and freezes, causing damage to the wood on the inside.

- Cup shakes: – caused by rupture of tissue in a circular direction.

- Ring shakes: – results from the pulling apart of two or more growth rings.

Twisted fibers or Wandering Hearts ⟹ are caused by the twisting of young trees by fast-blowing wind in one direction. Defects in Timber.

Upsets:- Indicate wood fibers that are injured by crushing or compression.

Excrescences:- are formed when the tree has received a certain shock or injury so that the growth of the tree is completely upset and irregular projections appear on the body of timber.

Defect Due to Conversion (Defects occur during converting timber to commercial form)

Chip mark:- or sign placed by chip on the finished surface of timer.

Diagonal grain:- Due to improper sawing of the timer

Torn Grain:- Due to the falling of the tool, the impression is formed.

Wane:- Original rounded surface still present on the fabricated wood item.

Defects Due to Fungi (The attack on timber by fungi, when moisture content is more than 20%)

Blue Stain:- Fungi attack the sapwood of timber and the color is changed to blue.

Brown Rot:- certain fungi feed over cellulose of timber section due to which it assumes brown color and the defect is termed as brown rot.

- Dry Rot:- Converting the wood into dry powder. The tendency of these defects increases in the absence of sunlight and the presence of dampness around the timber section.

- Heart rot:- A fungus called heart rot makes the wood in the middle of the trunk and branches deteriorate. Through cracks in the bark, fungi penetrate the tree and eat away at the heartwood.

- Sap Stain:- The sapwood loses its color because of feed on cell contents of sapwood.

- Wet Rot:- Chemical decomposition of wood of the timber and timber converts to grayish brown powder known as wet rot. The tendency to develop these defects increases if the timber section is not seasoned properly.

- White Rot:- Certain fungi feeds over the lignin and convert the appearance of white mass.

Defects Due to Seasoning

When wood is seasoned, the following flaws might arise:-

- Bow: – curvature formed in the direction of the length of the timber is called bow.

- Check: – A check is a kind of crack that separates fibers, but it doesn’t extent from one end to another.

- Cup: – unequal shrinkage in radial and tangential direction.

- Honey-combing: – stress is developed in the heartwood during the drying process or seasoning. For these stresses, cracks are created in the form of a honeycomb texture.

- Split: – split is a special type of check. in this separation of the grain from one end to another takes place.

- Twist

- Warping: – is deviation from flatness as a result of stresses and uneven shrinkage due to uncontrolled and non-uniform loss of water.

- Chucks:- small cracks caused due to rapid drying.

MISCELLANEOUS INFORMATION

- Timber is an anisotropic material.

- The strength and weight values of timber are generally standardized at 12% water content.

- To prevent lateral buckling minimum width of the beam is kept equal to or more than L/50 and D/3.and the width should not be less than 50mm.

- Well-seasoned timber contains moisture content in the range of 10-12%. (IS 1141-1993)

- The strength of the timber is maximum In the direction parallel to the grains and minimum perpendicular to the direction of the grains.

DEFLECTION OF TIMBER

- When beam-supporting brittle coverings like AC sheets, earthenware, slates, gypsum, etc. then maximum deflection should not be more than span/360. Otherwise, deflection of span/ 240 is allowed.

- In the case of the cantilever deflection should not exceed clear span/180.

- Sir Able’s process is used to make timber fire-resistant. In this process, sodium silicate paste is applied to the surface of the timber and then a concentrated solution of silicate soda is applied to it.

- Fire resistance can also be provided by soaking it in the solution of ammonium sulfate.

Application of timber obtained from different trees:-

- BABUL: – used for bodies of bullock carts, tool handles agricultural instruments, etc.

- BENTEAK: – furniture construction works, building construction and boat construction, etc.

- MULBERRY: – used for sports goods, baskets, hockey sticks tennis rackets, cricket bats etc.

- BIJASAL: – ordinary building construction, cartwheel, furniture, etc.

- SHISHAM OR SISSOO:- since it is strong durable and tough and takes fine polish hence is used for high-class furniture, plywoods, bridge poles, sports goods, railway carriages, etc.

- TEAK WOOD:- high quality and durable furniture, shipbuilding, railway carriage, well kerbs, piles, house construction, etc.

- SANDALWOOD:- used for agricultural implements, wheels, mallets, boxes, fancy goods.

- DEODAR:- it provides soft wood and is used for making cheap and rough furniture, railway sleepers, packing boxes, structural work, etc.

In structural timber the longitudinal elastic modulus is about 10-20 times that of the radial or tangential elastic modulus. Defects in Timber

Some important IS CODES for timber:-

- IS 1141-1958 – seasoning of timber

- IS 399-1963 – classification of commercial timber and their zonal distribution.

- IS 1708-1969- test of timber performed in the laboratory.

- IS 4970-1973- identification of commercial timber.

- Built-up columns are made by spiking, nailing, or bolting together planks or square sections. In nailed joints, it is found that the diameter of hole should not be greater than 4/5 of the diameter of the nail and that the diameter of nails must lie within ¼ and 1/6 of the least thickness of timbers to be connected.

- Shrinkage of green timber is least along its length about 0.1% along the length, 3-5% along the radial direction, and 10-15% along the circumferential direction.

- Laminated timber is used for cantilever arches, bows, string trusses, etc.

- For scantling heartwood is used while for paneling plywood is used.

- Fiberboards are used for insulation against heat and sound. Fiberboards are rigid boards that are prepared by processing a steamed mass of wood, dust wool, or other vegetable fibers and hard pressed to a thickness approx 3 mm to 12 mm.

Empty cell process: – they are now the most common method of treating of wood with waterborne preservatives. The empty cell process is designed to obtain deep penetration with minimum net retention of preservatives. This should always be used for treatment with oil preservatives if provides the desired retention.

There are two types of empty cell process:-

1. LAWRY PROCESS: – in this, a cylinder is loaded with a charge and then closed. Now preservatives are filled in the cylinder with a pressure of about 3.5-12.5 kg/cm2 till they achieve the required absorption.

2. RUEPING PROCESS: – there is a slight difference from the above process in this cylinder is first subjected to an air pressure of about 2- 5 kg/cm2 for a specified period. This pressure is maintained while filling the cylinder with preservatives and then antiseptic pressure is applied till the required absorption is obtained.

If a timber beam is having span of L and cross section b x d then is said to be laterally supported only if,

1. d/b < 3 and

2. L/b <50.

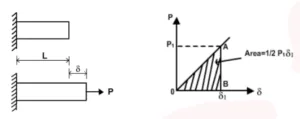

On application of external forces timber behaves as an elastic material.

Impreg timber: – such timbers are fully or partially covered with resin. The resin employed is phenol pharmeldihyde. Then is cured at a temperature of 150-1600c. their trade name is sunmica, sunglass, formica etc.

Advantages:- it is not affected by weather conditions and moisture, electrical insulator, resist acidic effects, has expansion of 25-40% less than ordinary timber also durable and strong.

Compreg timber: – The strength and durability of such timber is less than impreg timber. curing is done under pressure same as impreg timber. Their specific gravity varies in the range of 1.3-1.35

Also Read:- Surkhi Mortar

Post Comment