Temperature Effects, Grades, HYSD vs TMT, and Design Basics

Concrete is strong in compression but weak in tension. To overcome this limitation, reinforcement steel is provided in concrete structures. In this article, we will discuss the temperature effects on concrete, types and grades of reinforcement steel, HYSD and TMT bars, their stress–strain behavior, and basic design methods, explained in a clear and practical manner.

Temperature Effect on Reinforced Concrete

Thermal Contraction and Shrinkage

Thermal contraction in concrete produces effects similar to shrinkage. When concrete cools down, it tends to contract, which can lead to cracking if not properly controlled.

To reduce cracks caused by temperature variation and shrinkage, a small amount of nominal reinforcement, commonly known as temperature and shrinkage reinforcement, is provided in concrete members such as slabs and walls.

Thermal Expansion of Steel and Concrete

The coefficient of thermal expansion of:

- Steel ≈ 12 × 10⁻⁶ /°C

- Concrete ≈ 10 × 10⁻⁶ /°C

Since both values are nearly equal, no significant relative movement occurs between steel and concrete under temperature changes. This compatibility makes reinforced concrete a reliable composite material.

Purpose of Reinforcement in Concrete

Reinforcement steel is provided in concrete to:

- Resist tensile stresses, as concrete has negligible tensile strength

- Improve ductility

- Control cracking

- Enhance structural safety and durability

Grades and Types of Reinforcement Steel

Commonly Used Grades (as per IS standards)

The reinforcement grades generally used in construction are:

- Fe 250 – Mild Steel (MS bars)

- Fe 415

- Fe 500

Types of Reinforcing Bars

- Mild Steel (Plain bars) – Fe 250

- HYSD bars (High Yield Strength Deformed bars) – Fe 415, Fe 500

HYSD bars may be manufactured by:

- CTD (Cold Twisted Deformed) process

- TMT (Thermo-Mechanically Treated) process

Mechanical Properties of Steel

Yield Stress, Ultimate Stress, and Elongation

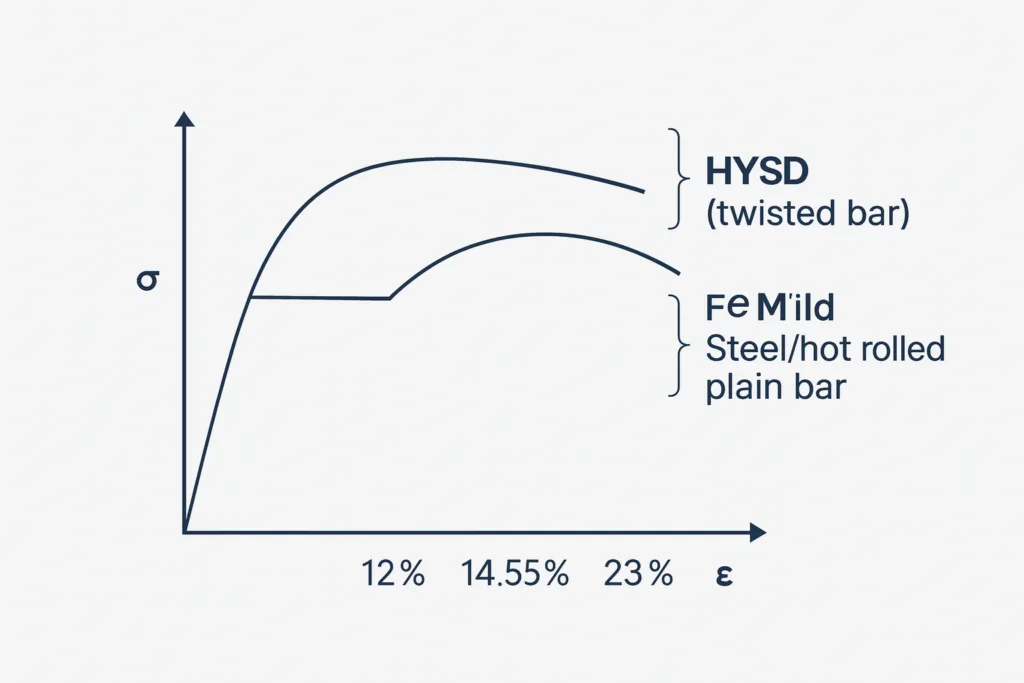

| Grade | Yield Stress (MPa) | Ultimate Stress (MPa) | % Elongation |

| Fe 250 | 250 | 412 | 23% |

| Fe 415 | 415 | 485 | 14.5% |

| Fe 500 | 500 | 545 | 12% |

- The yield strength mentioned above is the minimum guaranteed value.

- Actual strength may be higher.

- The specified yield strength is treated as the characteristic strength of steel.

For all grades of steel:

- Modulus of Elasticity (Es) = 2 × 10⁵ MPa (in tension and compression)

Cold Working (CTD Process)

Cold working involves stretching and twisting mild steel beyond the elastic limit and then releasing the load.

Effects of Cold Working

- Eliminates the yield plateau

- Increases yield strength

- Reduces ductility

- Reduces the difference between yield stress and ultimate stress

- Introduces residual stresses

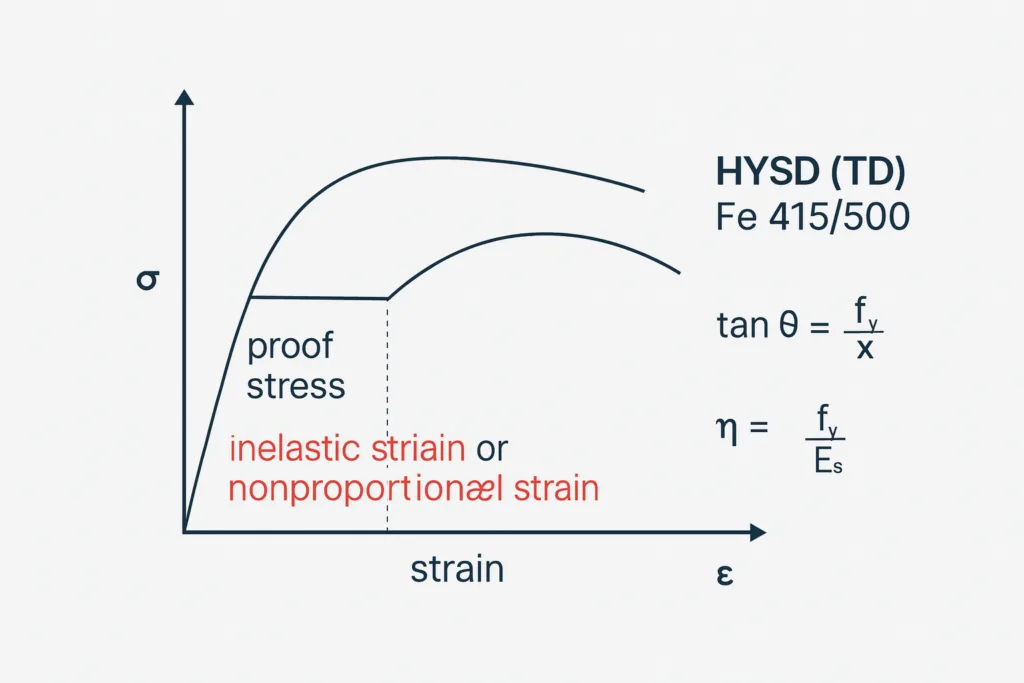

In HYSD (CTD) bars, the yield strength is defined as 0.2% proof stress.

Proof Stress (0.2% Proof Stress)

Proof stress is defined as:

- The stress at which non-proportional strain of 0.002 occurs, or

- The stress, which, upon unloading, leaves a residual strain of 0.002

Disadvantages of HYSD (CTD) Bars

HYSD bars manufactured by the CTD process have several drawbacks:

- Low ductility and difficulty in bending

- Higher corrosion risk due to induced stresses

- Poor fire resistance

- Lower weldability

- Not suitable for stress reversal and dynamic loading (e.g., earthquakes)

TMT Bars (Thermo-Mechanically Treated Bars)

TMT bars are hot-rolled HYSD bars that are rapidly cooled using a quenching process (water cooling).

Microstructure of TMT Bars

- Outer layer: Martensite (provides strength)

- Inner core: Ferrite–Pearlite (provides ductility)

The stress–strain curve of TMT bars is similar to that of mild steel, making them superior to CTD bars.

Advantages of TMT Bars

- High ductility (almost like MS bars)

- Better corrosion resistance

- Good fire resistance

- Excellent weldability

- Suitable for stress reversal and seismic loading

This is why TMT bars are preferred in earthquake-resistant structures.

Size of Reinforcement Bars

Reinforcing bars are available in nominal diameters from 5 mm to 50 mm.

Nominal diameter is defined as the diameter of a plain round bar having the same mass per meter length as the deformed bar.

Commonly Used Bar Diameters and Areas

| Bar Diameter (mm) | Area (mm²) |

|---|---|

| 6 | 28 |

| 8 | 50 |

| 10 | 78.5 |

| 12 | 113 |

| 16 | 201 |

| 20 | 314 |

| 25 | 490 |

| 28 | 615 |

Design Methods in Reinforced Concrete

Over time, three main design philosophies have evolved:

- Working Stress Method (WSM)

- Ultimate Load Method (ULM)

- Limit State Method (LSM) – Currently adopted in IS 456

The Limit State Method ensures:

- Safety against collapse

- Serviceability under working loads

- Economy and reliability

Reinforcement steel plays a crucial role in the performance of reinforced concrete structures. Understanding temperature effects, types of steel, stress–strain behavior, and manufacturing processes like CTD and TMT helps engineers make safer and more economical design decisions. Today, TMT bars combined with the Limit State Method form the backbone of modern RCC design.

Temperature Effects, Grades, HYSD vs TMT, and Design Basics

FAQ Section (Very Good for SEO & AdSense)

❓ Why is temperature reinforcement provided in concrete?

Temperature reinforcement is provided to control cracks caused by thermal contraction and shrinkage of concrete. It does not increase strength but improves durability.

❓ Why steel and concrete work well together?

Steel and concrete have nearly the same coefficient of thermal expansion, so they expand and contract together without causing internal stresses.

❓ What is the difference between HYSD and TMT bars?

HYSD (CTD) bars are cold twisted and have lower ductility, while TMT bars are thermo-mechanically treated and offer higher ductility, better corrosion resistance, and seismic performance.

❓ What is 0.2% proof stress?

It is the stress at which steel shows a permanent strain of 0.002 after unloading. For HYSD bars, yield strength is defined using proof stress.

❓ Which design method is used in RCC today?

The Limit State Method (LSM) is currently used as per IS 456, ensuring safety, serviceability, and economy.

- Creep of Concrete: Definition, Mechanisms, Effects & Long-Term Deflection Explained:- https://engineerlatest.com/creep-of-concrete-explained/#google_vignette

- Shrinkage in Concrete: Types, Causes, Effects & Design Considerations Explained:– https://engineerlatest.com/shrinkage-in-concrete-types-effects-design/

- The Arch bridges and Cantilever Bridges:- https://engineerlatest.com/the-arch-bridges-and-cantilever-bridges/

- Steel Bridges Types and Benefits:- https://engineerlatest.com/steel-bridges-types-and-benefits/

- Truss Bridges, Types, Design Benefits, and Components Overview:- https://engineerlatest.com/truss-bridges-types-design-benefits-and-components-overview/

- Footings and Foundations Explained: Types, Functions, and IS 456 Guidelines:- https://engineerlatest.com/footings-and-foundations-explained/

- Back Stay Analysis in Tall Buildings | Direct vs Indirect Lateral Load Path Explained:- https://engineerlatest.com/back-stay-analysis-in-tall-buildings-direct-vs-indirect-lateral-load-path-explained/

Post Comment