Working Stress Method (WSM) in RCC – Theory, Assumptions and Permissible Stresses

Table of Contents

Introduction to Working Stress Method (WSM)

The Working Stress Method (WSM) is the earliest and traditional method of design used in reinforced concrete structures. This method was widely used before the introduction of the Limit State Method (LSM).

In WSM, structures are designed based on working loads (service loads), and the stresses developed in concrete and steel are kept within permissible limits to ensure safety and serviceability.

This method is based on elastic theory and is mainly used today for academic understanding, comparison of design philosophies, and basic conceptual clarity.

Basic Concept of Working Stress Method

The fundamental idea of WSM is that:

If stresses in materials are kept well below their ultimate strength, the structure will remain safe.

In this method:

- Concrete and steel are assumed to behave in a linear elastic manner

- The design stresses are limited by applying a factor of safety on material strength

- Failure is avoided by ensuring that stresses do not exceed permissible stresses

Assumptions of the Working Stress Method

The Working Stress Method is based on the following key assumptions:

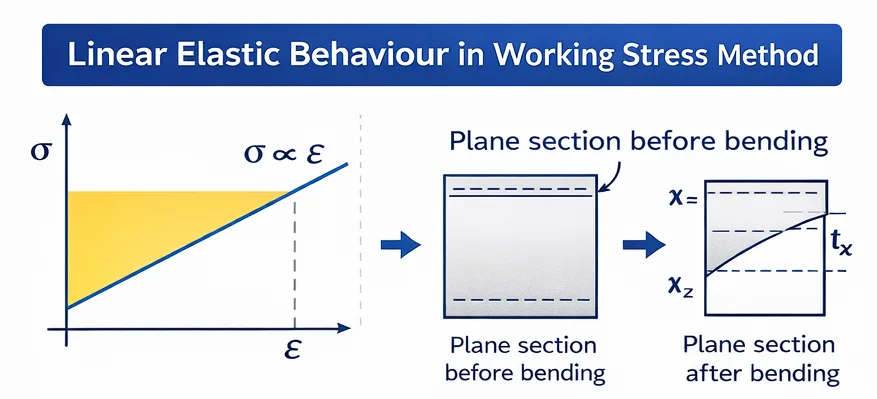

- Linear Elastic Behavior

Structural materials follow Hooke’s Law: σ=Eε. Stress is directly proportional to strain. - Low Stress Level

Induced stresses due to working loads are kept below permissible values. - Working Load Analysis

The structure is analysed only under working load/service load. - No Load Factors

Unlike LSM, no load factors are applied in WSM. - Material Safety

Safety is ensured by applying a factor of safety on material strength, not on loads.

Because of these assumptions, WSM is also known as the Modular Ratio Method.

Permissible Stress Concept

In WSM, design is governed by permissible stresses.

Permissible stress is defined as:

This ensures that stresses in materials remain within elastic limits under service conditions.

Permissible Stress in Concrete

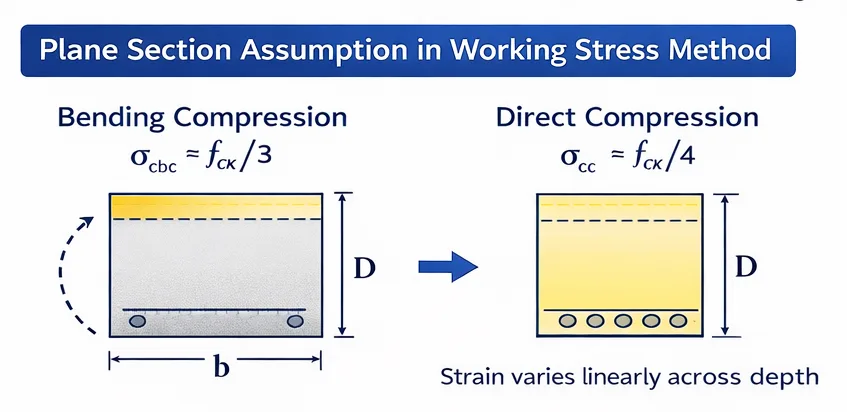

The permissible stress in concrete depends on:

- Grade of concrete

- Type of stress (bending, compression, or direct compression)

Permissible Stress Values in Concrete

| Grade of Concrete | Bending Compression σ_{cbc} (MPa) | Direct Compression σ_{cc} (MPa) |

|---|---|---|

| M20 | 7 | 5 |

| M25 | 8.5 | 6 |

| M30 | 10 | 8 |

📌 Important points:

- Permissible bending compression stress ≈ fck / 3

- Permissible direct compression stress ≈ fck / 4

- Bending stress is kept higher due to stress redistribution in flexure

Permissible Stress in Steel

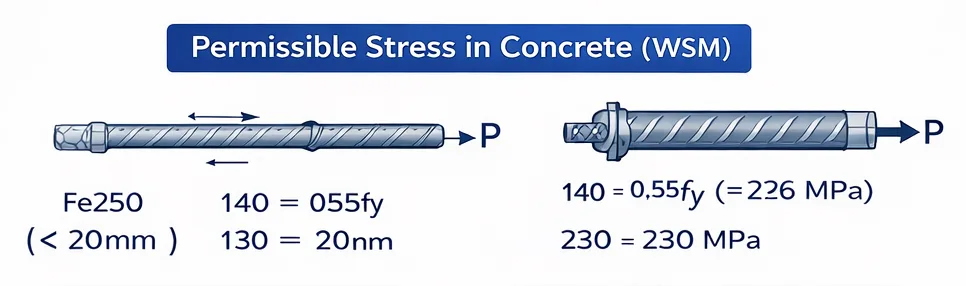

The permissible stress in steel depends on:

- Grade of steel

- Type of stress

- Diameter of reinforcement bar

Permissible Stress Values in Steel (WSM)

| Type of Stress | Fe 250 (MPa) | Fe 415 (MPa) |

|---|---|---|

| Tension (ϕ < 20 mm) | 140 | 230 (≈ 0.55 f_y) |

| Tension (ϕ ≥ 20 mm) | 130 | 230 |

| Compression | 130 | 190 |

📌 Notes:

- Smaller diameter bars allow better strain distribution, hence higher permissible stress

- These permissible stresses are not applicable to water tank design under WSM

- σ_{st} represents permissible stress in steel

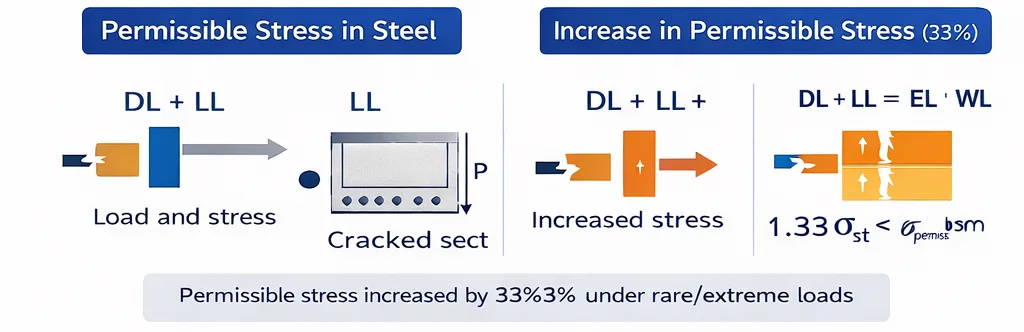

Increase in Permissible Stress (33⅓%)

In extreme loading conditions such as:

- Dead Load + Live Load + Wind Load

- Dead Load + Live Load + Earthquake Load

The permissible stress in materials may be increased by 33⅓%.

Reason:

- The probability of the occurrence of extreme loads is very low

- This provision improves the economy without compromising safety

Advantages of the Working Stress Method

- Simple and easy to understand

- Based on elastic theory

- Ensures good serviceability (crack control & deflection)

- Useful for conceptual learning

Limitations of the Working Stress Method

- Does not represent the actual non-linear behavior of materials

- No clear margin against collapse

- Leads to an uneconomical design

- Not suitable for modern RCC and seismic design

Due to these limitations, WSM has been largely replaced by the Limit State Method.

Working Stress Method (WSM) in RCC – Theory, Assumptions, and Permissible Stresses

The Working Stress Method played a crucial role in the development of reinforced concrete design. Although it is no longer preferred for practical design, understanding WSM is essential for students, interviews, and a foundation of RCC behavior.

- Creep of Concrete: Definition, Mechanisms, Effects & Long-Term Deflection Explained:- https://engineerlatest.com/creep-of-concrete-explained/#google_vignette

- Shrinkage in Concrete: Types, Causes, Effects & Design Considerations Explained:– https://engineerlatest.com/shrinkage-in-concrete-types-effects-design/

- The Arch bridges and Cantilever Bridges:- https://engineerlatest.com/the-arch-bridges-and-cantilever-bridges/

- Steel Bridges Types and Benefits:- https://engineerlatest.com/steel-bridges-types-and-benefits/

- Truss Bridges, Types, Design Benefits, and Components Overview:- https://engineerlatest.com/truss-bridges-types-design-benefits-and-components-overview/

- Footings and Foundations Explained: Types, Functions, and IS 456 Guidelines:- https://engineerlatest.com/footings-and-foundations-explained/

- Differences Between IS 1893:2016 and IS 1893:2025 for Earthquake Resistant Design:- https://engineerlatest.com/differences-between-is-18932016-and-is-18932025-for-earthquake-resistant-design/

Post Comment