Demystifying Formwork in Construction: DOKA Formwork System and Components

Table of Contents

Formwork

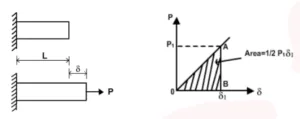

Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the mould. Formwork can be made using moulds out of steel, wood, aluminium and prefabricated forms. The construction of formwork takes time and involves expenditure of up to 20-25% of the cost of the structure or even more.

The system of Formwork adopted by some construction companies is the DOKA Formwork system which is an Austrian company.

Various components of Formwork are heavy-duty towers (HDT), walers, U-heads, H-beams, plywoods, splices for connecting walers, Tower Spindle, Footplate, Flange claw assembly, climbing cone, head adapter assembly.

The type of formwork used in some construction sites is already pre-manufactured by the company in Chennai. The formwork used in sites has a specified dimension of walers, heavy-duty towers, H-beams etc.

A crucial component of the concrete construction process is formwork. It offers the concrete that has just been poured the support and confinement it needs to grow strong enough to stand on its own. Without formwork, it would be difficult, if not impossible, to shape complicated structures like columns, beams, walls, and slabs.

DOKA Formwork System

Due to its effectiveness, adaptability, and dependability, the Austrian DOKA Formwork method has become widely used in the construction sector. This system has been adopted by L&T, a well-known company in construction, to improve project outcomes and construction procedures. We will examine the essential qualities and advantages that distinguish the DOKA Formwork system as a top pick.

Main Types Of formwork Systems:

- Formwork arrangement for walls and columns

- Formwork arrangement for flat slabs

- Formwork arrangement for beams

- H-beams

- Heavy-duty tower system

- Stair tower system

Formwork Arrangement for walls and Columns:

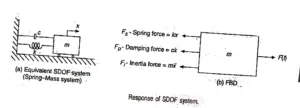

For both walls and columns, plywood sheathing is supported by H-beams, backed by steel walers. This assembly facilitates fixing working platforms for access, checking of reinforcement, concreting etc.

The entire panel, along with the platform and alignment system can be shifted using cranes as a single unit. Panels are created in workshops at the site and the assembly of components is reduced, enhancing the accuracy throughout. Since the entire unit is handled as a whole, the loss of smaller components is reduced and contributes to material productivity.

Formwork arrangement for flat slabs

Salient features

- The formwork arrangement provides flexible spacing and arrangement options.

- Simplicity in shuttering and de-shuttering results in high labour productivity.

- The formwork arrangement guarantees a clean, accurate, and smooth concrete finish.

- Suitable re-propping increases material productivity.

Formwork arrangement for beams

Salient Features

- The formwork arrangement in Site for beams eliminates the use of timber for beams’ sides and beam bottoms.

- It requires only the cutting and placing of plywood.

- The arrangement is easy to assemble, align and fix.

- It is easier in this arrangement to level and obtain an accuracy of dimension.

- The system also facilitates easy De-shuttering.

H-beams

Salient features of H-beams

- The beams used in the Site formwork system reduce timber consumption to a significant level.

- The simplicity of not only H-beams but the whole system contributes to

minimizing labour. - The H-beams are dimensionally stable, uniform in size, and consistent in

strength.

The H-beams used are much more economical and long-lasting.

Heavy-duty tower system

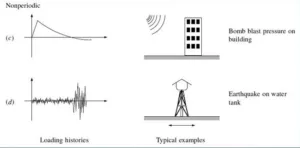

The Heavy duty tower system is widely used as staging for heavy floors at higher altitudes and also serves as scaffolds o certain occasions. Heavy-duty frames are braced using standard bracing, forming the heavy-duty tower system. Couplers and pins connect frames together, ensuring verticality. Spindles provided at the bottom can be used to adjust height and level. At every 6m interval, the towers are braced with permanent structures that prevent the tower from twisting under abnormal loading conditions.

Heavy Duty tower System used in the Bridge construction in Powerhouse.

Stair tower system

A unique building solution called the stair tower formwork system is intended to make it easier to build solid, straight staircases. This system, which is an essential component in multi-story buildings, is designed to offer stability, accuracy, and ease of assembly, making it a great asset for construction projects of various sizes.

Advantages of Pre-Manufactured Formwork

- Time and Cost Considerations:- Formwork construction is a laborious operation that needs experienced personnel, plenty of time, and money. We will clarify the elements that affect formwork construction’s time and cost consequences, which can total up to 20–25% of the project’s overall cost.

- Safety and Quality Assurance in Formwork Implementation:- Formwork has an impact on the finished structure’s safety and structural integrity in addition to its appearance. We’ll talk about how crucial it is to follow safety regulations when installing forms, and we’ll emphasize Company’s dedication to using formwork that is of the greatest caliber.

Tunnel Formwork System

In the concrete lining of the tunnel, a CIFA gantry has been used in providing the shuttering to the tunnel. It consists of a movable Gantry and the Shuttering for the Lining of the Tunnel. The gantry used in this project is 2.5 crores.

The gantry operates inside the whole formwork system. It consists of 2 main parts that are inverted and overt. Overt further consists of 3 parts that are:

End toe

Piers

Vault

It also has jacks which are used to fold and unfold the shutter and place them and align them where the concreting is required.

Vibrators are also present in the gantry for proper compaction so that no air voids are left while concreting.

Gantry Shifts 4 shutters at a time a total length of 6m on both sides, and the total length of the shutters is 24m. So, the Length of one shutter is 1.5m each.

Hydraulic cylinders Shrink and the shutters also shrink Downwards at the time of De-shuttering and expand at the time of Shuttering.

The invert of the Formwork rests on the Stool post which is Tightened with the help of Impactor.

Deshuttering Of gantry

Firstly the invert deshuttering starts in which the working platform is brought from the backside to the front side. The deshuttering work of the overt starts from the end toe which is lifted up by unlocking the hydraulic cylinder and fixing them with the traveller. Then the piers are folded and finally, the vault is closed and shifted to the front side for shuttering purpose

Deshuttering work of Gantry

Disadvantage of Gantry

The major disadvantage of Gantry is that it can be used only once. Once the work is over then it can’t be used again at another site because It is designed for a particular diameter of the tunnel.

Also Read- PLANT AND MACHINERY ARE USED IN TUNNEL CONSTRUCTION

Recommended Books on Formwork & Concrete Construction

Formwork for Concrete Structures:- https://amzn.to/3QIhFvZ

Concrete Formwork Systems:- https://amzn.to/4h4XeEm

1 comment